EMI Shielding Product Category

-

Torstran™ is a new range of carbon nanotube sheet (CNT) materials and fibres that have been developed by Tortec and supported by research conducted at Cambridge University Engineering Department. These materials are manufactured using an innovative gas plasma process that forms a unique 3D array of interconnected carbon nanotubes.

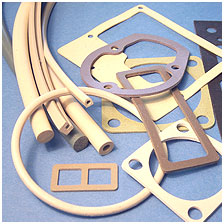

High performance electrically conductive elastomers in EPDM, silicone and fluorosilicone. These gasket materials provide EMI shielding and environmental sealing. -

High performance EMI gasket materials that provide optimal shielding effectiveness & excellent environmental sealing.

High performance electrically conductive elastomers in EPDM, silicone and fluorosilicone. These gasket materials provide EMI shielding and environmental sealing. -

Precise guidance of a fluid dispensing nozzle under CNC control for continuous application of intricate, small cross-section gaskets directly onto component or substrate contours.

Precisely guiding fluid dispensing nozzles under CNC control to enable the continuous application of intricate, small cross-section gaskets (0.35 – 2.0mm) directly onto the contours of a component or substrate. -

For a variety of RFI/EMI shielding and grounding applications – conductive flexible and structural conductive adhesives.

Flexible electrically conductive adhesives that can be used for EMI shielding and grounding – Including our equivalent to CA811 and BS100. -

Conductive, high strength, permanent metal to metal bondsideal for assembly of metallic enclosures negating the use of fasteners, welding or machining operations.

Pastes and compounds for form in place applications. These can be conductive and non conductive to be used for EMI shielding and environmental protection. -

Electrically conductive materials comprising of a silicone RTV and conductive particles. Easily applied to panel joints/seams and small clearances.

Conductive composite materials designed to be applied to small gaps, joints and seams. When cured it prevents water ingress and improves the shielding performance of joints. -

An effective, thin EMI gasket material providing a watertight or pressure seal where sealing faces have a flatness tolerance of >0.05mm

Conductive woven or expanded metal meshes for EMI shielding. -

A combination gasket available in a variety of permutations of mesh and elastomer, to combine excellent EMI performancewith dust, environmental, or pressure sealing capability.

Solid knitted mesh combined with elastomer to create a high performance shielding and environmental sealing gasket. -

Monel, Aluminium, Stainless Steel or Tin plated Copper clad Steel wire into continuous sections or strips. A range of tough, resilient gasket sections that offer excellent shielding performance.

Solid knitted mesh, elastomer cored knitted mesh, knitted mesh tape sections and combination gaskets. -

Ideal for development production capable of up to 100 off runs, the 3D printed parts can be made in a range of polymers including ABS and polypropylene, as well as specialist conductive plastics. Added EMI shielding protection can also be applied in the form of our anti static/conductive or shielding paints.

3D Printing and Rapid Prototyping

3D printing and rapid prototype service allows cost effective prototype development. Ideal for development production capable of up to 100 off runs, the 3D printed parts can be made in a range of polymers including ABS and polypropylene, as well as specialist conductive plastics. Added EMI shielding protection can also be applied in the form of our anti static/conductive or shielding paints. These are also available separately for you to apply yourselves. Working with the customer, Shielding Solutions offers a full design service. Once approved, Shielding Solutions will 3D print the design enabling the customer to trial his prototype product prior to committing to expensive metal machining or moulding. Boxes, enclosure, or indeed any other plastic part can be 3D printed offering the customer low cost, small runs, negating the use of expensive traditional tooling which also demands high minimum run quantities. The simplest and quickest method to get your design 3D printed is to send us your 3D model file which we can then convert and load into our systems. We recommend Electromagnetic Testing Services Ltd to test EMI shielding products in your application. For more information, please Contact Us -

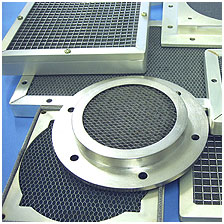

Low-cost EMI Vent Panels for use with 40mm, 60mm, 80mm, 92mm & 120mm fans. Available ‘off the shelf’ for fast delivery.

We stock a range of Low cost EMI Vent Panels for use with 40mm, 60mm, 80mm, 92mm & 120mm fans. They provide EMC shielding where applications demand a low cost solution, whilst still providing an adequate shielding performance. These are available 'off the shelf' for fast delivery and significantly more cost effective if small volume shielding vents are required. Plastic Housing/Honeycomb filter Single Layer Honeycomb A Hi-impact ABS UL94-HB fire retardant moulding is fitted with one layer of 3.2mm cell x 6.35mm thick honeycomb and a nickel over copper plated fabric over foam gasket to ground the honeycomb to the metalwork. The vents have 4 countersunk holes to suit standard fan mountings.

Shielding Effectiveness Measured performance in accordance with MIL-STD 285 (80mm tested)

Frequency Field Typical (db) 200kHz H 53 100Mhz E 102 500MHz P 85 2GHz P 74 10GHz P 58

Double Layer Honeycomb A Hi-impact ABS UL94-V0 fire retardant moulding is fitted with two layers of honeycomb at 90 degrees (cross cell) to ach other. One layer of 3.2mm cell x 3.2mm thick honeycomb, one layer of 3.2mm cell x 5mm thick honeycomb and a nickel over copper plated fabric over foam gasket to ground the honeycomb to the metalwork. The vents have 4 countersunk holes to suit standard fan mountings.Part No Hole Pitch Thickness Height/Width SSvent40 32.0mm 8mm 45.5mm SSvent60 50.0mm 9mm 66.0mm SSvent80 71.5mm 10mm 84.5mm SSvent92 82.0mm 10mm 97.0mm SSvent120 104.0mm 10mm 125.0mm

Shielding Effectiveness Measured performance in accordance with MIL-STD 285 (80mm tested)

Frequency Field Typical (db) 200kHz H 88 100Mhz E 130 500MHz P 115 2GHz P 101.5 10GHz P 91.5

Aluminium Frame/Stainless media Aluminium/Stainless filters offer high levels of air passage while efficiently filtering contaminants and shielding EMI/RFI. Their tightly woven stainless corrugated mesh screen offers the highest performance. Designed to fit all 60mm, 80mm, 92mm, 120mm and 162mm tube axial fans, filters may be mounted directly onto the fan or to any other housing.Part No Hole Pitch Thickness Height/Width SSvent40/2 32.0mm 8.4mm 46.5mm SSvent60/2 50.0mm 12.5mm 64.9mm SSvent80/2 71.5mm 12.5mm 84.8mm SSvent92/2 82.0mm 12.5mm 96.9mm SSvent120/2 104.0mm 12.5mm 126.3mm

Shielding Effectiveness Measured performance in accordance with MIL-STD 285 (80mm tested)

Frequency Field Typical (db) 200kHz H 59 100Mhz E 115 500MHz P 92 2GHz P 77 10GHz P 66

We recommend Electromagnetic Testing Services Ltd to test EMI shielding products in your application. For more information, please Contact UsPart No Hole Pitch Thickness Height/Width LCV003-60 50mm 4.5mm 60mm LCV003-80 71.5mm 4.5mm 800mm LCV003-92 82.5mm 4.5mm 92mm LCV003-120 104.8mm 4.5mm 120mm LCV003-127 113.3mm 4.5mm 127mm -

Shielding Ventilation Panels and filters primarily designed to allow unrestricted air-flow whilst preventing the transmission of electromagnetic interference (EMI).

EMI shielded vent panels including high performance and RoHS compliant aluminium honeycomb types with optional air filter panels and kick-plates. -

A range of conductive paints and coatings to suit most requirements and can be applied to most surfaces to provide flexible and hardwearing conductive and antistatic finishes.

Acrylic and polyurethane based resins to produce a conductive coating that can be easily brushed or sprayed on to provide electro static protection of 109Ω or less. -

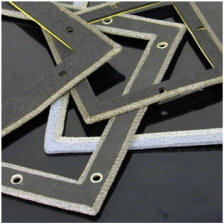

Electrically conductive fabric over-foam gasket sections are formed by wrapping a conductive (or metallised) fabric over a foam elastomer core. A synthetic textile yarn uniformly plated throughout its cross-section to provide consistent low resistivity.

Conductive fabric wrapped foam core gasket sections that offer low compression force and high shielding performance. -

Manufactured from beryllium copper foil, resilient/compliant to provide low-contact resistance between mating faces giving excellent EMI shielding performance. Very low closure force, light gauge foil sections available.

Beryllium copper and stainless steel finger strip gasket sections with various profiles and mounting options. -

Arange of Connector Gaskets material types. Low and high compression forces, corrosion problems, high temperatures and poor fittings all overcome by appropriate material selection.

Conductive embedded wire gasket materials to cut to suit many standard sized connectors which require EMI shielding and/or environmental sealing. -

Copper foil, Aluminium foil, Tinned Copper foil and Nickel over copper metallised synthetic textile yarn tapes.

Conductive fabric and foil EMI shielding tapes. -

Effective isolation of board level components and the most cost-effective production method. Being custom made, the cans can be manufactured toincorporate a range of design features to suit individual applications.

Board level EMI shielding cans are manufactured by photo etching or pressing thin metal sheet, which is then folded and soldered or tabbed to form the shielding can. -

A service for bonding windows or components together without the need for complicated assembly methods.We can assemble your free issued windows and other materials using our dedicated equipment or we can manufacture and supply the required components and assemble them in house.

Combining Acushield® and Bondshield® provides a service for bonding windows or other components together without the need for complicated assembly methods. -

Allowing the transmission of light whilst preventing the transmission of electromagnetic interference or EMI. An antireflective finish to improve the viewing characteristics of the window.

Windows and display filters that shield against EMI and can offer environmental sealing to IP68. -

Conductive elastomer and form in place compounds available to purchase and process yourself. With our expertise and in-house compounding facility, we can provide any specification of paste that you may require giving the longest possible product shelf life and reducing waste.

Pastes and compounds for form in place applications. These can be conductive and non conductive to be used for EMI shielding and environmental protection.