Conductive shielding tape offers excellent conductivity, conformability and durability in a thin, lightweight and flexible design.

Conductive Fabric Tapes

Our conductive fabric tape is based on a nickel over copper metallised synthetic textile yarn that is uniformly plated throughout its cross-section providing consistent low resistivity. Furthermore this arrangement ensures that this type of EMI shielding tape is particularly resistant to abrasion as ‘fresh’ plated fibres are continually exposed as the outer surface wears.

This type of EMI shielding gasket section has several advantages

- Good shielding performance – typically 90 – 110dB

- Extremely good wear characteristics

- Available with adhesive backing enabling easy fitting

- Tape construction provides extra flexibility

- Available in a wide range of sizes

- Non flammable to UL94-V0

This tape is typically available on 50m rolls 10-1000mm wide.

Conductive Foil Tapes

We offer a range of conductive metal foil tapes that are suitable for many grounding and EMI shielding purposes. The range of tapes offered are:

Aluminium

Copper

Tin plated copper

The copper and tinned copper tapes are readily solderable

These tapes can be supplied to any width in rolls up to 1.2m wide. The rolls are 20 or 33m long depending on type and are usually in stock in 10, 12, 25, 50, 100, and 125mm wide.

Options

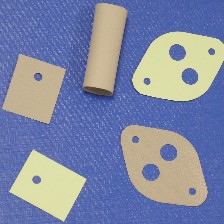

All tape types are available either with non conductive adhesive, conductive acrylic adhesive or without adhesive (plain foil). The adhesive backed versions can be wound on a release liner or self wound. They are also available as individual die cut foils.

All tape types are very conformable allowing them to be applied to irregular or contoured surfaces. As such they are suitable for a wide range of EMI shielding and ESD control applications as outlined below:

- Improving the EMI shielding of sheet metalwork seams/jointsli>

- Grounding ITO coated films for ESD protection of displays

- Terminating shielded windows and display back shields

- Creating shielded enclosures by lining plastic covers and enclosures

- Shielding of static cable assemblies / conduit

- General test and development work

We can supply pre-cut / formed components from these tapes so that they are easily assembled into or fitted into their intended location

In order to achieve the best possible electrical performance it is important that the surface it is to be applied to is not only clean but free of any oxidation /corrosion.

Typical (approximate) properties of copper and tinned copper tapes

| Thickness – foil only | 30 microns |

| Thickness – with release backing | 80 microns |

| Adhesion – peel strength | >4N/cm |

| Elongation | ≤5% |

| Tensile strength | 40N/cm |

| Temperature range | -20°C – +150°C |

| Shielding performance – up to 1Ghz | >50dB |

Typical (approximate) properties of aluminium tapes

| Thickness – foil only | 35 microns |

| Thickness – with release backing | 80 microns |

| Adhesion – peel strength | >4N/cm |

| Elongation | ≤5% |

| Tensile strength | 25N/cm |

| Temperature range | -20°C – +150°C |

| Shielding performance – up to 1GHz |

We recommend Electromagnetic Testing Services Ltd to test EMI shielding products in your application.

For more information, please Contact Us