Supershield® Conductive Elastomers are a group of high performance EMI gasket materials that provide an optimal combination of superior shielding effectiveness combined with excellent environmental sealing. Conductive elastomers are produced by dispersing conductive metal particles in an elastomer carrier (normally silicone or fluorosilicone) forming a homogenous gasket material with high conductivity.

There are a range of conductive fillers and elastomer combinations that are suitable for virtually any application that may be encountered.

CEM-NC001 meets the requirements of ASTM E-595-07 for low outgassing applications

| Material Code | Material |

|---|---|

| SA001 | Silicone Silver Aluminium |

| FSA001 | Fluorosilicone Silver Aluminium |

| FSA003 | Passivated Fluorosilicone Silver Alumiium |

| NC001 | Silicone Nickel Graphite |

| FNC001 | Fluorosilicone Nickel Graphite |

| NC002 | Flame Retardant Silicone Nickel Graphite |

| SC001 | Silicone Silver Copper |

| FSC001 | Fluorosilicone Silver Copper |

| SN001 | Silicone Silver Nickel |

| S001 | Silicone Silver |

| N001 | Silicone Nickel |

| FN001 | Flurorosilicone Nickel |

| NA001 | Silicone Nickel Aluminium |

ECE Comparison Table

| Material | CEM-SA001 | CEM-FSA001 | CEM-FSA003 | CEM-NC001 | CEM-FNC001 | CEM-NC002 |

|---|---|---|---|---|---|---|

| Elastomer | Silicone | Fluoro-silicone | Fluoro-silicone | Silicone | Fluoro-silicone | UL94 V0 Silicone |

| Filler Type | Ag/Al | Ag/Al | Pass Ag/Al | Ni/C | Ni/C | Ni/C |

| Colour | Light Tan | Green | Blue | Dark Grey | Dark Grey | Dark Grey |

| Density | 2.0 gcm−3 | 2.0 gcm−3 | 2.0 gcm−3 | 2.0 gcm−3 | 2.0 gcm−3 | 2.0 gcm−3 |

| Hardness Range | 30-80 Shore A | 70 Shore A | 70 Shore A | 30-80 Shore A | 60 Shore A | 60 Shore A |

| Volume Resistivity | <0.01Ωcm | <0.01Ωcm | <0.01Ωcm | <0.5Ωcm | <0.05Ωcm | <0.05Ωcm |

| Attenuation 10MHz to 10 GHz (MIL-STD-285) | 100-120dB | 100-120dB | 100-120dB | 100-120dB | 100-120dB | 100-120dB |

| Recommended Compression | 10 - 25% | 10 - 25% | 10 - 25% | 10 - 25% | 10 - 25% | 10 - 25% |

| Elongation | 350% | 310% | 310% | 450% | 270% | 300% |

| Compression Set | <20% | <20% | <20% | <20% | <20% | <20% |

| Temperature Range | -55℃ to 160℃ | -55℃ to 160℃ | -55℃ to 160℃ | -55℃ to 160℃ | -55℃ to 160℃ | -55℃ to 160℃ |

ECE Comparison Table cont....

| Material | CEM-SC001 | CEM-FSC001 | CEM-SN001 | CEM-S001 | CEM-N001 | CEM-FN001 |

|---|---|---|---|---|---|---|

| Elastomer | Silicone | Fluoro-silicone | Silicone | Silicone | Silicone | Fluoro-silicone |

| Filler Type | Ag/Cu | Ag/Cu | Ag/Ni | Ag | Ni | Ni |

| Colour | Tan | Green | Tan | Tan | Dark Grey | Green |

| Density | 4.5 gcm−3 | 4.5 gcm−3 | 4.5 gcm−3 | 2.0 gcm−3 | 4.5 gcm−3 | 4.9 gcm−3 |

| Hardness Range | 60 Shore A | 70 Shore A | 60 Shore A | 50-60 Shore A | 60 Shore A | 70 Shore A |

| Volume Resistivity | <0.01Ωcm | <0.01Ωcm | <0.01Ωcm | <0.01Ωcm | <0.01Ωcm | <0.01Ωcm |

| Attenuation 10MHz to 10 GHz (MIL-STD-285) | 100-120dB | 100-120dB | 100-120dB | 100-120dB | 100-120dB | 100-120dB |

| Recommended Compression | 10 - 25% | 10 - 25% | 10 - 25% | 10 - 25% | 10 - 25% | 10 - 25% |

| Elongation | 480% | 220% | 300% | 400% | 470% | 340% |

| Compression Set | <20% | <20% | <20% | <20% | <20% | <20% |

| Temperature Range | -55℃ to 125℃ | -55℃ to 125℃ | -55℃ to 160℃ | -55℃ to 160℃ | -55℃ to 160℃ | -55℃ to 160℃ |

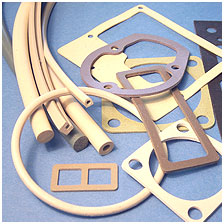

Conductive elastomers are extremely versatile and are available in the following forms

Moulded Sheets

All of our Supershield conductive elastomers materials are available in sheet form, from 0.3mm thick and generally to any size you require up to 380mm x 500mm. They are also available with a reinforced interlayer from 0.8mm thick.

Extrusion

An extremely wide range of cross-sections are available including ‘O’ sections, ‘D’ sections, ‘U’ channels, square/rectangular strip as well as custom sections to suit specific applications. Some profiles, such as ‘O’ and ‘D’ sections can be produced as hollow sections where lower compression forces are required or a greater tolerance range must be accommodated

Gasket sections can be supplied in continuous lengths, cut lengths or joined to form gaskets. Gaskets produced in this way are joined by ‘vulcanising’, that is to say that a small piece of the original material is used to form the joint using heat and pressure producing a very high quality gasket. Extruded conductive elastomer profiles can be joined to form rings e.g. ‘o’ rings, picture frames (mitred joints) or more complex shapes.

In general terms this is the most efficient means of producing gasket sections or gaskets using conductive elastomers

Solid round sections are available from 0.8mm upwards in increments from 0.1mm

Hollow round sections are available with a 1.2mm (outside diameter) upwards in increments of 0.1mm.

Please let us know if you have a special requirement.

Moulded and Vulcanized O-Rings

These are seals that can be produced from our full range of conductive elastomer materials and may provide a high level of EMI shielding as well as protection against water and dust ingress in hostile environments. These seals typically have a circular cross-section but can be produced in a range of other cross-section profiles, such as D sections, to suit individual applications.

The most commonly used method to manufacture these types of seals is to cut an extruded section to the required length and bond using heat and pressure (vulcanise) using a matching compound to effectively produce a continuous gasket. This method has the advantage that the gaskets can be produced much more efficiently and at lower cost than equivalent moulded parts. Another noteworthy feature of this method is that it allows the seal to be produced with hollow sections greatly reducing compression force required for the seal which can be important in some lower rigidity enclosures.

Moulded o-rings are usually produced in a range of (standard) smaller sizes for connector shells and the like.

For some applications where it can be difficult to position the seal a custom moulded o-ring can be moulded to the exact shape of the part that it is to be assembled in.

All of the seals referenced above can also be supplied in a range of non-conductive elastomers for applications where only an environmental or hermetic seal is required.

Moulded pre-form then die-cut

This is the preferred method for producing ‘flat’ gaskets such as waveguide and connector gaskets. The material is moulded as a sheet or ‘frame’ and then as a secondary operation the gaskets are punched out. This technique allows economical production of parts, saving material in the case of larger gaskets and enabling many smaller parts to be punched from a single moulding

Custom mouldings

Conductive elastomers may be moulded directly to form specific parts such as cable glands, complex gaskets, insert mouldings etc.

All of the above fabrication methods are suitable for both low and high volumes

Uncured Compound

Our range of conductive elastomers are available in uncured catalyzed compound. It can be supplied by the kg or lb and rolled into logs, tubs, or sheets as requested.

General properties

Very high shielding possible with appropriate flange/enclosure materials and finishes – typically attenuation figures comfortably in excess of 100dB can be achieved up to 10GHz

- Hardness range 30 – 80 Shore A

- Good ‘H’ field (magnetic) shielding performance

- Environmental sealing up to IP68 possible

- Very long service life even in hostile conditions – 20 years not uncommon

- Remain serviceable even at temperature extremes – typically -55°C to +150°C – lower and higher temperatures are possible

- Low out-gassing

- Variants based on fluorosilicone elastomer have excellent resistance to long-term contact with oils, fuels and other organic liquids or contaminants

- Versions available that can survive repeated exposure to high induced currents – EMP (Electromagnetic Pulse) applications

Applications

Conductive elastomers find uses in many different applications and generally where a combination of very high shielding and environmental protection are required from a single gasket. They were originally mainly used for military applications but more efficient production methods along with increasing more demanding uses in commercial equipment have seen their use become more widespread. Typical uses include

- Military radio and communications equipment

- Aerospace – flight system control units

- Base stations

- Waveguide and connector gaskets

We recommend Electromagnetic Testing Services Ltd to test EMI shielding products in your application.

For more information, please Contact Us