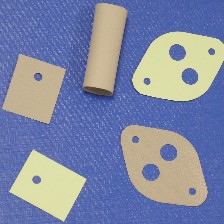

Thermally conductive electrically insulating interface materials produced from glassfibre supported silicone elastomer with ceramic oxide fillers, Thickness range 0.18mm to 0.5mm, Thermal conductivity 0.8 to 5 WmK, Voltage breakdown 1kV to >6kV, Electrically conductive graphite pads, Thickness 0.2mm, Thermal conductivity 3.8WmK

All available as sheets or die cut parts. Pressure sensitive adhesive an option.

Typical Applications

- AC/DC power supplies

- Audio amplifiers

- Automotive

- Power generators

- UPS

Features and Benefits

- Thermal impedance range from 0.13 – 0.6°C-in /watt at 50 psi

- High dielectric strength of >6,000 volts AC

- Resistant to tears and cut through

- UL recognized materials File No. E180840

Thermal Materials

See the specifications of the materials we offer are below.

Warth Materials

| Material | K381 | K200 | K230 | K177 | K228 | PK17 | PK23 | KK071 |

|---|---|---|---|---|---|---|---|---|

| Thickness mm | 0.381 | 0.200 | 0.23 | 0.177 | 0.228 | 0.229 | 0.229 | 0.071 |

| Breakdown Voltage 50Hz rms | 4000 | 1000 | 4500 | 3500 | 4500 | 5500 | 4500 | 4500 |

| Approx Thermal Resistance (T0-3 Transistor) oC/W | 0.2 | 0.28 | 0.35 | 0.45 | 0.50 | 0.45 | 0.35 | 0.45 |

| Thermal Conductivity Wm−1K−1 | 3.36 | 1.3 | 1.07 | 0.79 | 0.79 | 0.80 | 1.05 | 0.25 |

| Hardness Shore Micro | 85 | 80 | 80 | 80 | 80 | 90 | 90 | 90 |

| Tear Resistance kN/m | 50 | 50 | 75 | 50 | 50 | 125 | 250 | 95 |

| Tensile Strength MPa | 10 | 20 | 30 | 16 | 16 | 35 | 55 | 69 |

| Dielectric Constant 1000Hz | 3.5 | 2.5 | 2.6 | 2.6 | 2.6 | 3.18 | 3.12 | 1.9 |

| Elongation % | 30 | 30 | 35 | 30 | 30 | 20 | 35 | 44 |

| Continuous Use Temp. oC | -60 to +180 | -60 to +180 | -60 to +180 | -60 to +180 | -60 to +180 | -20 to +150 | -20 to +150 | -60 to +180 |

| Colour | White | Light Green | Pink | Grey | Grey | Lilac | Yellow | Yellow |

K381 – Ultra high performance silicone elastomer loaded with Boron Nitride. Suitable for military or commercial high power applications. Meets UL 94V-0

K200 – Constructed with coated glass fibre with a specially loaded silicone compound. Conforms to UL 94V-0

K230 – Silicone rubber compound coated onto a layer of glassfibre with highly thermally conductive filler. Suitable for military and Aerospace industries. Conforms to UL 94V-0

K177 and K228 – Silicone rubber compound coated onto a layer of glassfibre. Suitable for military and Aerospace industries. Conforms to UL 94V-0

PK17 and PK23 – Polyester coated Glassfibre Thermally conductive Insulators. Suitable for applications where silicone would cause contamination problems. Conforms to UL 94V-0

KK071 – A combination on Kapton MT and a synthetic resin adhesive on one side. Conforms to UL 94V-0

Laird Tgard Materials

| Material | Tgard 210 | Tgard 220 | Tgard 230 | Tgard 20 | Tgard 300 | Tgard 400 |

|---|---|---|---|---|---|---|

| Thickness mm | 0.25 | 0.51 | 0.76 | 0.076 | 0.23 | 0.23 |

| Breakdown Voltage VAC | 6000 | 10000 | 20000 | 9000 | 6000 | 5500 |

| Thermal Impedance @100psi oC-cm2/W | 1.17 | 2.26 | 2.28 | 3.9 | 2.65 | 3.82 |

| Thermal Conductivity W/mK | 5 | 5 | 5 | - | - | - |

| Hardness Shore A | 85 | 80 | 80 | - | 75 | 90 |

| Dielectric Constant 1000Hz | 3.32 | 3.32 | 3.32 | 1.8 | 3.3 | 3.3 |

| Continuous Use Temp. oC | -60 to +200 | -60 to +200 | -60 to +200 | -40 to +150 | -60 to +180 | -60 to +180 |

| Colour | White | Blue | Green | White | Yellow | Gray |

| UL Flammability Rating | 94 V0 | 94 V1 | - | 94 V0 | 94 V0 | 94 V0 |

| Material | Tgard 500 | Tgard 3000 | Tgard 5000 | Tgard TNC-5 | Tgard K52-1 | Tgard K52-2 | Tgard K52-3 |

|---|---|---|---|---|---|---|---|

| Thickness mm | 0.23 | 0.13 | 0.127 | 0.127 | 0.051 | 0.076 | 0.1 |

| Breakdown Voltage VAC | 6000 | 6000 | 6000 | 6000 | 4200 | 7800 | 9000 |

| Thermal Impedance @100psi oC-cm2/W | 2.13 | 2.83 | 2.06 | 1.94 | 0.84 | 1.42 | 1.94 |

| Thermal Conductivity W/mK | - | - | - | - | - | - | - |

| Hardness Shore A | 80 | 80 | 75 | - | - | - | - |

| Dielectric Constant 1000Hz | 3.3 | 3.3 | 3.4 | 3.8 | 1.8 | 1.8 | 1.8 |

| Continuous Use Temp. oC | -60 to +180 | -60 to +180 | -60 to +180 | - | -60 to +150 | -60 to +150 | -60 to +150 |

| Colour | Brown | Brown | Tan | Brown | Light Amber | Light Amber | Light Amber |

| UL Flammability Rating | 94 V0 | 94 V0 | 94 V0 | 94 V0 Pending | - | - | - |

For further information, please Contact Us.