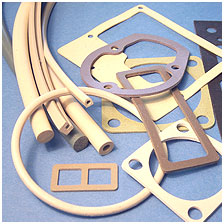

The wide selection of Connector Gaskets material types will accommodate most of your specifications.

Low and high compression forces, corrosion problems, high temperatures and poor fittings can all be overcome by careful selection of material. Where required, we can also supply adhesive-backed gaskets for quick and easy mounting. For more detailed information on the various gasket materials, please refer to the relevant sections of this catalogue.

Some of the commonly used sizes are listed here but we can also supply gaskets to suit most standard part sizes. For those not listed, please submit a detailed drawing, being sure to indicate the bulkhead side of the gasket.

|

For use with MIL-C-38999 Series I and II Connectors |

||||||

| Shell Size |

Dimensions |

Weaveshield |

Supershield | |||

|

C |

B |

A |

D |

Fluorosilicone/ |

Fluorosilicone/ |

|

|

9 |

18.3 |

16.9 |

24.4 |

3.60 |

IWG-FSA001-00227A01 |

CEM-FSA001-00227A01 |

|

For use with MIL-DTL-83528 Connectors |

||||||

| Shell Size |

Dimensions |

Weaveshield | Supershield | |||

|

C |

B |

A |

D |

Fluorosilicone/ |

Fluorosilicone/ |

|

|

9 |

23.8 |

14.2 |

18.3 |

3.30 |

IWG-FSA001-00230A01 |

CEM-FSA001-00230A01 |

|

Other Regular Sizes & Materials |

|||||||||

| Shell Size |

Dimensions |

Weaveshield |

Multishield |

Supershield |

|||||

|

C |

B |

A |

D |

Neoprene 0.5mm |

*Silicone |

*Silicone 1.5mm |

*SA001 |

*SC001 |

|

|

8 |

15.09 |

12.70 |

22.23 |

4.37 |

58-108 |

58-208 |

35-208 |

66-308 |

86-308 |

| * Prefix part number with ‘F’ for Fluorosilicone. (e.g. F58-208) | |||||||||

The three main elastomer types are:

Silicone ZZ-R-765 2B 40 – a 40 shore A hard silicone elastomer with excellent high temperature performance

Silicone sponge AMS 3195 – a sponge elastomer carrier where lower compression force is required

Fluorosilicone Mil-R-25988 50 – a fuel and oil resistant elastomer with a wide temperature operating range and excellent ageing characteristics

In combination with the above the two main wire types normally used are

Monel (copper/nickel) alloy – a corrosion resistant alloy that provides reliable long term shielding performance

Aluminium – where improved galvanic compatibility with aluminium enclosures is required.

The main elastomer types available are:

Silicone ZZ-R-765 2B 50 – a high specification silicone

Silicone AMS 3302D – a more general purpose silicone

Low out-gassing silicone ASTM 595-84 – a silicone elastomer with very low levels of condensable and non condensable volatiles

Fluorosilicone Mil-R-25988 – a fuel and oil resistant version of silicone

Synthetic elastomer AMS3222C – a high performance synthetic elastomer resistant to fuels and hot oil

We recommend Electromagnetic Testing Services Ltd to test EMI shielding products in your application.

For more information, please Contact Us