Shielded Window Material Types

Glass

Advantages – scratch resistance, resistance to solvents/chemicals, non-flammable

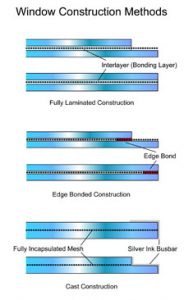

Usual construction method – fully laminated, sometimes edge bonded

Types – low coefficient of expansion borosilicate glass, toughened

Surface finishes – etched anti-reflective, magnesium fluoride or multilayer antireflective

Polycarbonate

Advantages – impact resistance/toughness, low density, low or non-flammable

Usual construction method – fully laminated, edge bonded

Types – UL94-V0 flammability or low smoke emission grades, range of tints

Surface finishes – scratch/mar, solvent and chemical resistant hard surface coating, this coating can be applied as

Acrylic

Advantages – clarity, low density

Usual construction method – fully laminated, cast or edge bonded

Types – wide range of tints

Surface finishes – scratch/mar resistant hard surface coating, antireflective coating

Cast polyester (CR39)

Advantages – clarity, low density, scratch resistance, high-temperature stability, resistance to solvents/chemicals

Usual construction method – cast or cast/laminated assembly

Types – wide range of tints

Surface finishes – ‘cast in’ anti-reflective finish

Special purpose polarising or contrast enhancement filters may be incorporated within windows. In particular cast windows lend themselves to this as the filter may be cast in at the time of manufacture.